If your business is based on products, rather than services, you need to know how to set up a warehouse. If you are a reseller, your success depends on a ready supply of the items you offer so that customer orders are fulfilled promptly.

If you are a manufacturer, your warehouse is the gathering point for your components and raw materials, as well as the launching point for packing and shipping your finished goods.

Whether you manage a large or small business, the right warehouse layout and equipment will enable you to move your material, manage your space and process your orders with optimum efficiency, supporting your sales and production operations and saving you time and money every day.

Start With a Warehouse Layout Strategy

Although the basic principles of efficient warehouse design are the same for every business, a warehouse setup is not right for your business unless it is based on a sound strategy for supporting the external and internal elements of your supply chain.

Your supply chain includes all of the entities and functions that are connected to your business, from the moment you take an order to the moment you fulfill the customer. The more deeply you analyze each element of your supply chain, the more you will realize how your warehouse layout strategy is shaped by these partnerships.

External Warehouse Partners

- Suppliers will determine the type, size and number of racks, shelves or bins needed for inbound material and whether space is needed to hold some goods on consignment.

- Transport companies will determine many of the tools and methods your shipping staff will use.

- Distributors and dealers will drive the product mix and package quantities required.

- Customers will provide feedback to improve your warehouse fulfillment operations.

Internal Warehouse Partners

- Marketing will determine which products to stock in the warehouse for various markets.

- Sales will provide the forecast of how much stock will be needed to meet demand.

- Accounting must closely monitor cash allocated to inventory and warehouse personnel.

- Purchasing and material planning will match material commitments and inventories with the changing level of anticipated sales.

- Quality must ensure that supplies in storage were properly inspected and approved for use.

- Manufacturing needs to be certain that no delays or shortages in warehouse operations are permitted to interfere with production.

- Customer service must fulfill every part of the customer expectation, with every order picked correctly, packed securely and shipped out on time and in full.

By listening to each of these partners and their sometimes competing priorities, you can gather the practical input to develop a winning warehouse layout strategy.

Need help insuring your warehouse or manufacturing business?

How to Choose Your Warehouse

- Proximity to Your Markets – With one shipping point, you can reach over 70 percent of the U.S. with two-day shipping. But is that good enough? With two shipping points, two-day shipping will reach 90 percent of the country, saving your customers money and enhancing their service experience.

- International Shipment – Will you need to receive or ship via a seaport or international airport? Is your shipping bay suitable for a cargo container loading? If you have a supplier in China, where will your goods clear customs? What is your backup plan if there is a strike at the port?

- Ground Shipment – Is your building on the regular routes for UPS and FedEx, or on a branch route? Should you have an emergency late in the day, how far is the drive to the hub? Will your shipping station accommodate software and label printers for all of the shippers you will use?

- Available Buildings – Your need for warehouse space may grow with your business…or may shrink, if you split locations or use customer consignment. In an area with many options, a local move will help you hold onto experienced workers and existing service relationships.

- Workforce Quality – Remember that you are not just shopping for space. You are also shopping for the locals who will handle your products, manage your team and serve your customers. Workers with more training cost more, but will improve team performance and service quality.

- Local Cost Factors – Rents, utilities and local taxes can vary widely, as well as safety and environmental regulations. Research operating costs and local codes to be certain that costs are in line with your budget and there are no surprises that could interfere with your operations.

- Special Tactics – Fit your strategy to your supply chain. If you have a special customer, it may make sense to store material next door to their plant to shorten lead times and payment cycles. Can you consign goods in a customer warehouse…or supplier goods in your own warehouse?

Capture Your Warehouse Features and Dimensions

Once you have chosen a promising building, study all of the features and dimensions of the warehouse. If you can get a blueprint, great. If not, then take the time with your own measuring wheel or tape to get the overall dimensions, ceiling height and distance to bay doors.

To draw a simple warehouse schematic, you can draw the walls and door openings on grid paper, adding cutouts so that you can try shelving and work spaces in different arrangements.

Warehouse layout is also very well supported by software products, both simple and high-end. A quick search for “warehouse layout software” will start you off with free apps and will proceed to sophisticated 3D warehouse simulators. If you prefer, you can also set up a warehouse drawing in a CAD system or with a simple drawing program, as we have in the examples below.

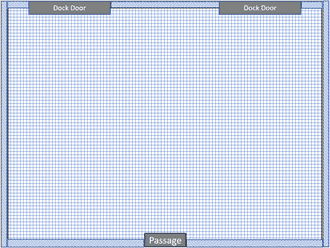

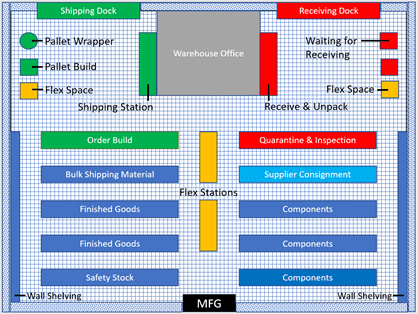

For the purpose of this discussion, we’ll envision a warehouse space with two overhead doors and one passage to another building. If your chosen space is smaller or has only one door, the general principles of warehouse layout and stock movement will remain the same and should still be considered for your design.

Starting grid for warehouse layout

Go With the Flow

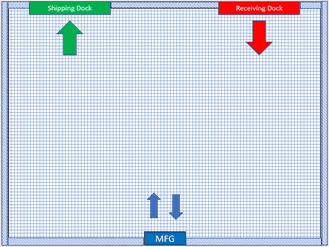

The primary design principle for warehouse space is unimpeded flow for receiving and shipping. For this example, we will discuss a manufacturing warehouse, since production adds a few more storage and movement considerations. However, the flow principles are the same for a retail or ecommerce warehouse.

Our warehouse will use one bay door for shipping and the other bay door for receiving. If your warehouse has only one large door, it is just as important to start your floor plan by visualizing the flow of received goods into the operation and the flow of finished products out the door.

The passage at the other end of the warehouse will be used for two-way traffic, with components and raw materials flowing to the manufacturing space and finished goods coming back to the warehouse to be ready for order fulfillment.

Flow from receiving and toward shipping

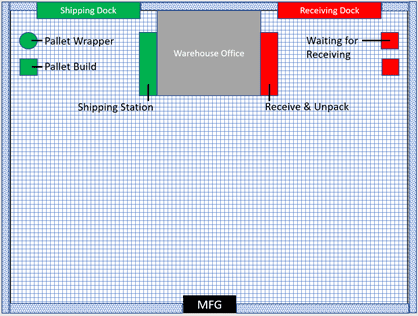

What do you need at the receiving dock?

Before planning your shelving or aisles, think first about the activity nearest the doors. Received goods must be matched with purchase orders and counts, and part numbers must be verified. All packages should have an initial inspection for damage, and all delivery details must be documented.

You will need a designated station to receive and unpack, as well as space for delivered pallets to wait while other deliveries are being processed. Pay careful attention to the amount of space needed to turn and reverse pallet loading equipment. On busy receiving and shipping days, workflow at the loading and unloading doors is always intense and can be dangerous.

What do you need at the shipping dock?

At your shipping dock, a shipping station will allow you to print bills of lading, container manifests, commercial invoices and other shipping documents, while capturing tracking numbers or other details provided by a transport driver.

This area is also the place to build, strap, shrink wrap and weigh pallets, just before they receive address labels, document pouches, customer order numbers and other identifiers for shipment.

You Need a Warehouse Office…or at Least a Desk

Since both shipping and receiving operations may need access to computers, printers, telephones and other desktop equipment, the dock area is a natural place to build your warehouse office. In a very small warehouse with only one door, this can simply be a shipping-receiving desk.

Operations Nearest to the Warehouse Doors

Keep the Flow Going – Incoming

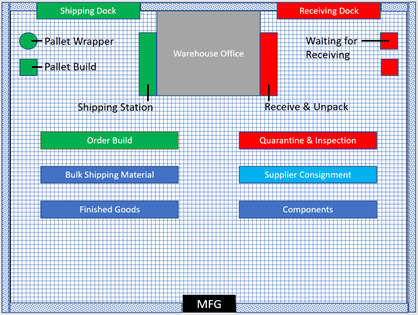

Keep efficient flow in mind as you begin to lay out your storage spaces, as shown below. If your quality system requires incoming inspection, the first shelving on the receiving side should be a quarantine area for received goods that have not yet been inspected and approved by quality control. In some warehouses, this area is locked behind chain link fencing to prevent components from being used without inspection.

Since you are closer to the dock but farther from the manufacturing process, you may also want to use the first rows of inflow shelving for special material, such supplier consigned goods.

Next, you will want to place the regular components and raw materials that are waiting to be routed to your manufacturing process.

Keep the Flow Going – Outgoing

On the shipping side, the flow is toward the dock. Finished goods can be stored closer to manufacturing if they are not going immediately to the dock. Closer to the doors, use storage space for your pallets, boxes, packing, strapping and other bulk shipping material.

Nearest the shipping door, an order build area allows products to be organized for bulk packing or pallets, such as multiple SKUs bound for the same customer or distributor.

Next, you will want to place your regular storage of finished goods that are waiting to be picked for orders.

Layout based on Flow from Receiving to Manufacturing to Shipping

Leave Open Space for Flexible Flow

Every warehouse has tides of activity that rise and fall throughout the day and the week. Your warehouse strategy – and floor plan – should include flex spaces (see below) where heavy deliveries can build up or where heavier-than-normal ship days can be processed.

In the central area between receiving and shipping, flex stations can be configured to break down larger quantities of incoming material to sort and shelve, or to pick and organize larger quantities of products for outgoing orders, as required.

Finally, our example shows both sides of the warehouse lined with light-duty wall shelving, which may be more suitable for smaller boxes and lighter merchandise. Wall storage in the warehouse may also be the best location for items that do not move as fast, or for unusual shapes, such as cantilever racks for bar stock or pipes.

Final layout includes workstations, storage areas and flex space

Visualize the Flow of Traffic

When your warehouse schematic is fully populated with work and storage spaces, visualize the normal traffic generated by the material handling equipment you plan to use, from hand trucks and rolling carts to pallet jacks and forklifts. And don’t forget stockers and pickers who are roving the aisles on foot.

If your products are suitable for hand trucks and rolling carts, aisle widths as tight as 6′ are feasible. A rolling ladder will require more width, and if you need to run a forklift, an aisle width of 12′ or more is standard.

Test Your Traffic Assumptions

Are your expectations realistic? Share your schematic with your stockers and equipment operators to make sure you haven’t based anything on an impractical assumption. If you have, the working pros can help you spot problems.

Try a Spaghetti Diagram

To perform an enlightening flow experiment, use a copy of the warehouse plan to draw visual flow lines, tracing the complete path of a received package into your warehouse – and the complete path of a shipment from production to storage and from storage to your shipping dock.

This exercise will help you identify unnecessary motion, redundancies, waiting and other forms of waste that interfere with efficient warehouse process flow. A spaghetti diagram also helps identify major intersection points (traffic jams) that may otherwise have gone unnoticed.

What type of shelving do you need?

The best storage shelves for your warehouse layout are the ones most suitable for the goods you will receive and ship. Your raw material shapes and component packaging will determine your shelving needs in receiving, and your product packaging will determine your shelving needs in shipping.

Pallet Shelving

- Pallet Shelving – With shelves deep enough for a 4’ pallet and steel frames rated for loading heavy and stacking high, pallet shelves are the best choice for bulky and heavy pallets, boxes and bins.

Heavy-Duty Shelving

- Heavy-Duty Shelving – If your products are heavy, but less bulky than a pallet, heavy-duty shelving provides 3’ to 4’ of depth and a solid frame suitable for heavy material, boxes and bins.

Light-Duty Shelving

- Light-Duty Shelving – If you will store lighter goods and stack no higher than 6’, light-duty shelving is economical and requires less space, with 18” to 24” depth and frames made of light metal or molded plastic. For added safety, your warehouse layout should place light-duty shelving against a wall, where it can be fastened for more support.

Cantilever Racks

- Cantilever Racks – Best suited for long and heavy raw material, such as bar stock or pipes.

Storage Bins

- Bins – Racks of bins or individual bins are suitable for small parts that are stored in loose quantity.

How should you label warehouse shelves?

For good warehouse storage and maximum picking, packing and shipping efficiency, you will need a shelf marking system based on the type of business you are in, the product identifiers you already use and your overall warehouse layout strategy for optimizing material flow.

Shelf Labeling by Part Number

If you are a manufacturer, the best way to label storage areas in your warehouse layout is with part numbers. The storage areas for your received components and raw materials can be labeled with your part numbers for those materials, and the storage areas for your finished goods can be labeled with your SKUs for those products.

Your build lists for assembly or manufacturing will show the part number (and location) needed for a production build, and each part can be checked off as it is picked and placed in a rolling cart for delivery to the manufacturing area.

Shelf Labeling with a Warehouse Address System

In a reseller warehouse layout with a high mix of similar products, it may make more sense to store according to product types, with all the printers together, all of the monitors together and so on. In this type of storage, you will need to develop an address system, which could be as simple as aisle, rack and shelf location. As long as your software allows you to enter a warehouse location, a pick list will guide even a new worker to the right storage area to pull the product and transfer it to the shipping area.

Where To Buy Warehouse Shelving and Equipment

You can source most types of heavy-duty shelving from domestic sellers, such as Uline and Global Industrial, or through international suppliers advertising on the marketplace Alibaba. Medium to light duty shelving can be found locally at DIY stores, including Lowes, Home Depot and even Walmart.

Depending on the weight, size and value of your products, you may also need work tables for packing and shipping, conveyors, scales, pallet jacks, a pallet wrapper, rolling stairs and rolling stock carts.

Pallet Jack

How to Save Money on Warehouse Shelving and Equipment

Study the equipment offered by the material handling equipment specialists, such as Uline and Global Industrial, and buy new if you can — but don’t overlook local sellers who may be advertising on Craigslist or other local marketplaces.

Forklift

As businesses expand, close up shop or move operations, there is always good used equipment for sale. If you go the used route, trust your own inspection of shelving, racks and carts, but bring along a skilled operator to inspect and test a forklift, pallet jack or other hydraulic equipment.

Go Live!

As you build your shelving, set up packing and shipping stations and get ready to receive, store and ship your products, test each element of your warehouse layout.

Are your aisles wide enough, or do your stockers need another foot? Can your pallets be handled safely at the full height of your racks? Are opposite flows causing traffic jams in storage areas? Have you given enough emphasis to streamlining your packing and shipping?

For more ways to test your warehouse layout, read up on the basics of lean warehouse management, which focuses on identifying and eliminating seven wastes: over-production, over-processing, transport, motion, waiting, inventory and defects. A quick search for “lean warehouse management” books will return suitable titles for every level of experience, from warehouse beginners to global supply chain professionals.

Keep Going…and Growing

Setting up your warehouse layout is just the beginning. As you learn more and apply what you learn to the real-world space and workforce you manage, every issue you identify is an opportunity for continuous improvement, helping you manage better processes, build better products, serve happier customers and keep your business growing. Need to insure your warehouse operation? Contact one of our business insurance specialists.